30++ Tab routing pcb machine

Home » Gym Workout » 30++ Tab routing pcb machineYour Tab routing pcb workout are ready. Tab routing pcb are a topic that is most popular and liked by everyone today. You can Get the Tab routing pcb files here. Find and Download all free photos.

If you’re searching for tab routing pcb pictures information connected with to the tab routing pcb keyword, you have come to the right site. Our site frequently provides you with suggestions for seeing the maximum quality video and picture content, please kindly hunt and locate more enlightening video content and graphics that fit your interests.

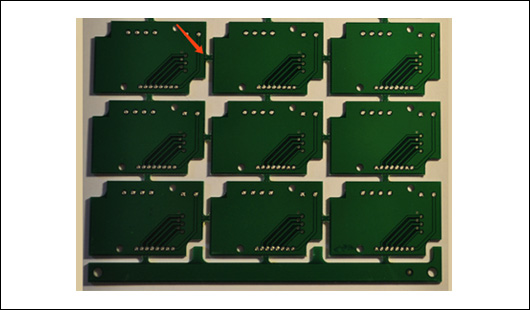

Tab Routing Pcb. When V-grooves cant be used design PCB arrays leaving perforated tabs routing space between PCBs. It is a breakthrough routing strategy that allows for. Thicker circuit boards are upwards of 0096 or 0125 use 0020 or greater when room allows for all features from the edge of the card. In the tab-routing panel in order to break the board off the panel after assembly V score or mouse bite holes can be used.

Pcb Panelisation Tips For Assembly Latest Open Tech From Seeed Studio From seeedstudio.com

Pcb Panelisation Tips For Assembly Latest Open Tech From Seeed Studio From seeedstudio.com

I prefer VGroving as you can get much closer groves less messy especially for the PCB makers and a much cleaner edge which you snap by hand. Fig 8 Tab-routing panel. It is a breakthrough routing strategy that allows for. If your PCB relies on the presence of edge-hanging components or components placed close to an edge some variation of tab-routing may be more appropriate than V-scoring. Not Sure If Your PCB Design Is Manufacturable. In the tab-routing panel in order to break the board off the panel after assembly V score or mouse bite holes can be used.

Tab Routing Panelization.

If your PCB relies on the presence of edge-hanging components or components placed close to an edge some variation of tab-routing may be more appropriate than V-scoring. If your PCB relies on the presence of edge-hanging components or components placed close to an edge some variation of tab-routing may be more appropriate than V-scoring. The three holes make it Tab Routed with Perforations A big advantage to tab routing is the ability to make boards in shapes other than rectangles. Three to five holes are often used in these perforation patterns. We recommend a 10mm clearance between Break routing this means if you use a 2mm routing tool then between PCBs the distance will be 14mm. You can still drill holes afterwards if that is what you meant.

Source: madpcb.com

Source: madpcb.com

Thicker circuit boards are upwards of 0096 or 0125 use 0020 or greater when room allows for all features from the edge of the card. Submit a FREE DFM Today. Keep traces and surface-mounted parts 18. In the tab-routing panel in order to break the board off the panel after assembly V score or mouse bite holes can be used. For printed circuit boards less than 0040 thickness always plan for routing using tabs only to avoid any issues.

Source: blog.epectec.com

Source: blog.epectec.com

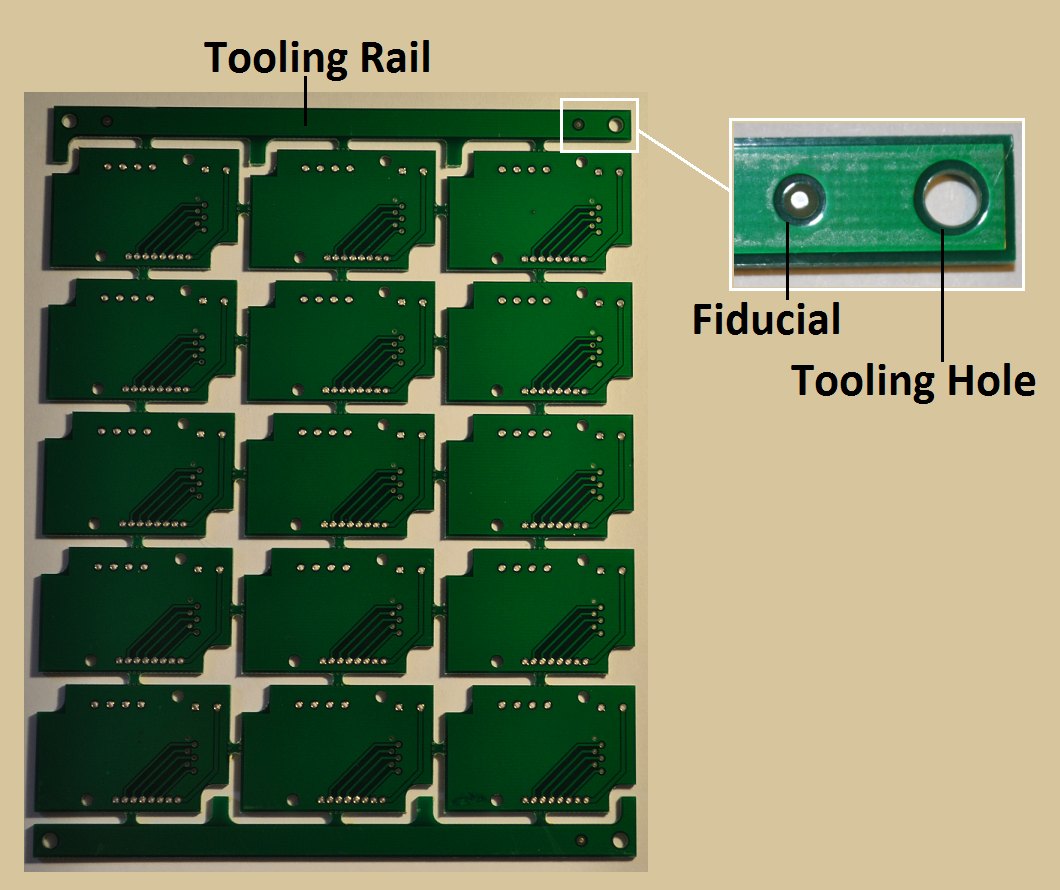

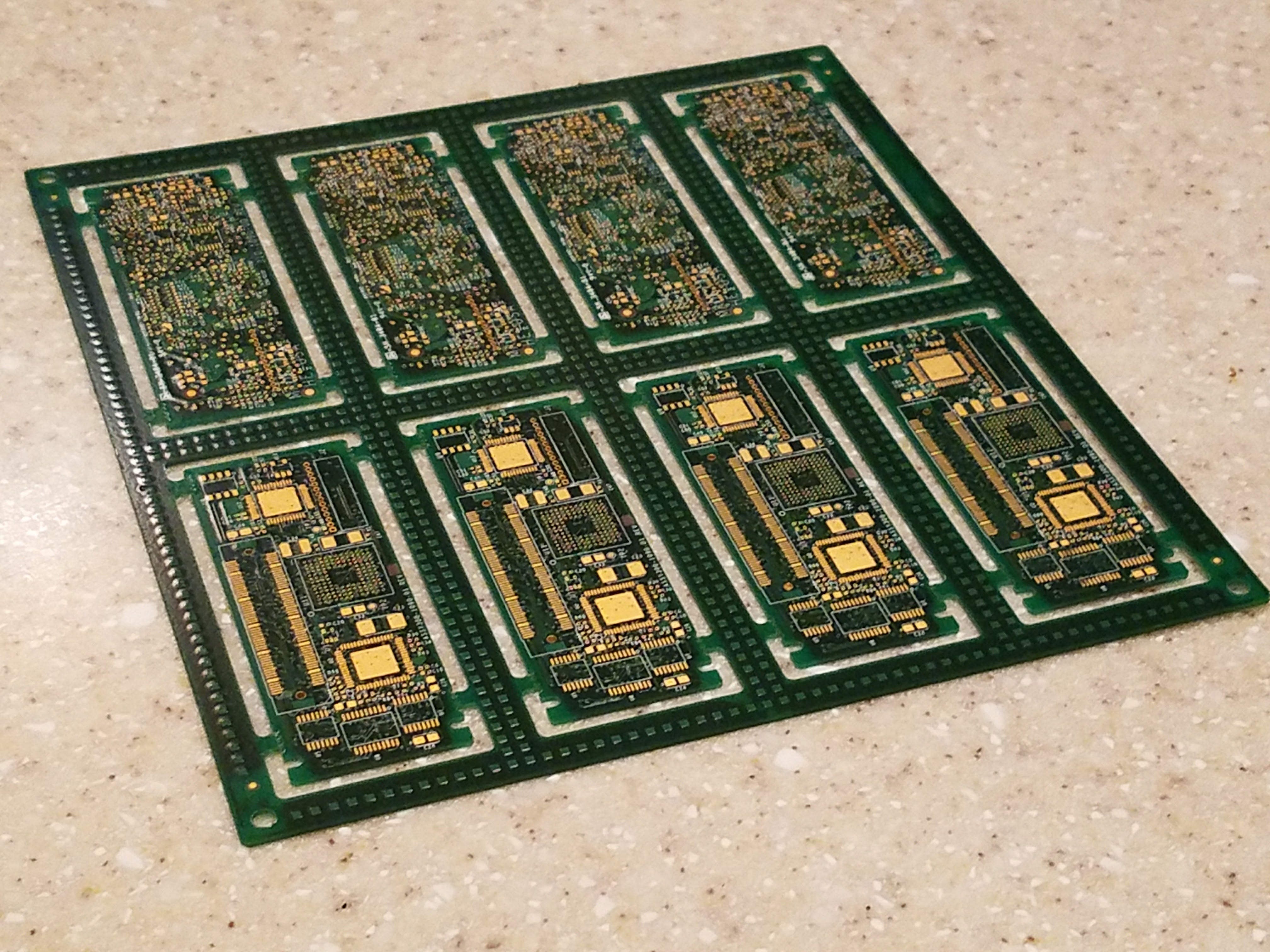

This is a tab-route panel in which the individual PCBs are connected by perforated tabs. Use wider panel borders. For square or rectangle boards V-scoring works well. A mix of scoring and tab routing can be used when some board sides are straight which can be scored while irregular sides must be tab routed. This is a tab-route panel in which the individual PCBs are connected by perforated tabs.

Source: allpcb.com

Source: allpcb.com

PCB arrays that cant feasibly use a V-groove method will instead use a tab routing method. Rather than completing the route path around the board edge Tabs are left so as to leave boards attached in pallets for ease in PCB assembly. On the down side it takes a bit more PCB material and can put a lot of stress on the area near the tab. Use wider panel borders. One of the benefits of tab-routing is that you can produce non-rectangular.

Source: forum.kicad.info

Source: forum.kicad.info

Also tab routing in high volumes takes a lot of time on the router and may drive your cost up. On the down side it takes a bit more PCB material and can put a lot of stress on the area near the tab. If you feel that breaking the PCB off the panel would cause too much stress on the PCB it is wise to use a special tool that will prevent board damage. Three to five holes are often used in these perforation patterns. Tab routing lets you place more than one board of either the same or different design into a given area.

Source: pinterest.com

Source: pinterest.com

This is a tab-route panel in which the individual PCBs are connected by perforated tabs. Thicker circuit boards are upwards of 0096 or 0125 use 0020 or greater when room allows for all features from the edge of the card. But keep in mind V score will give a clear edge after the boards are break away from the panels mouse bite holes will not give a clear edge. Break routing requires the placement of break-out-tabs on both the X Y of the PCB. By doing these two things you eliminate unneeded changes to the mechanical drawings.

Source: electronics.stackexchange.com

Source: electronics.stackexchange.com

This is a tab-route panel in which the individual PCBs are connected by perforated tabs. Thicker circuit boards are upwards of 0096 or 0125 use 0020 or greater when room allows for all features from the edge of the card. You should consider tab routing when your design has an irregular shape or if you need space between your boards to allow for overhanging components. Rather than completing the route path around the board edge Tabs are left so as to leave boards attached in pallets for ease in PCB assembly. Fig 8 Tab-routing panel.

Source: globalsources.com

Source: globalsources.com

Rather than completing the route path around the board edge Tabs are left so as to leave boards attached in pallets for ease in PCB assembly. Mouse bite holes is a line of holes works the same way as holes on array of stamps. A mix of scoring and tab routing can be used when some board sides are straight which can be scored while irregular sides must be tab routed. There are two ways to create PCB Breakaway Panels. You can still drill holes afterwards if that is what you meant.

Source: pcbuniverse.com

Source: pcbuniverse.com

Also tab routing in high volumes takes a lot of time on the router and may drive your cost up. On the down side it takes a bit more PCB material and can put a lot of stress on the area near the tab. This is a tab-route panel in which the individual PCBs are connected by perforated tabs. Tab routing is more appropriate when working with unusual shapes. If you feel that breaking the PCB off the panel would cause too much stress on the PCB it is wise to use a special tool that will prevent board damage.

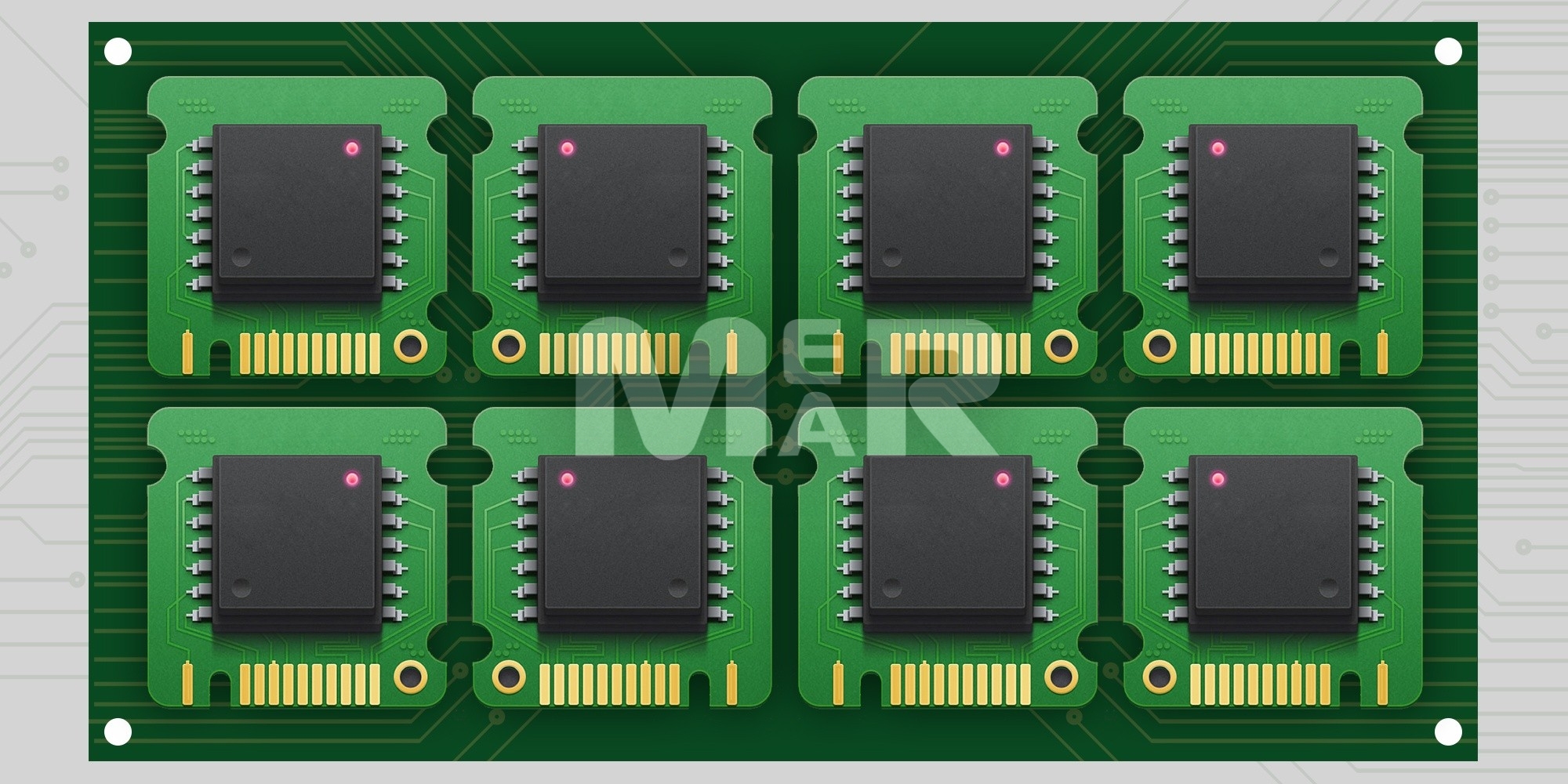

Source: mermarinc.com

Source: mermarinc.com

Keep traces and surface-mounted parts 18. PCB arrays that cant feasibly use a V-groove method will instead use a tab routing method. Tab routing is a popular PCB panelizing approach that uses tabs with or without perforations. When V-grooves cant be used design PCB arrays leaving perforated tabs routing space between PCBs. In the tab-routing panel in order to break the board off the panel after assembly V score or mouse bite holes can be used.

Source: pcbway.com

Source: pcbway.com

When V-grooves cant be used design PCB arrays leaving perforated tabs routing space between PCBs. Both of these methods allow engineers to get multiple boards manufactured and assembled at the same time using automated processes. When V-grooves cant be used design PCB arrays leaving perforated tabs routing space between PCBs. For square or rectangle boards V-scoring works well. The minimum accessible length to place these is.

Source: wellpcb.com

Source: wellpcb.com

Routing is done at the end of PCB manufacture and is quite stable unless you leave too little space. It is a breakthrough routing strategy that allows for. Rather than completing the route path around the board edge Tabs are left so as to leave boards attached in pallets for ease in PCB assembly. Submit a FREE DFM Today. I prefer VGroving as you can get much closer groves less messy especially for the PCB makers and a much cleaner edge which you snap by hand.

Source: quick-pcba.com

Source: quick-pcba.com

It is a breakthrough routing strategy that allows for. Tab Routing Tab routing is the best way to set up parts relative to the tooling process. If you feel that breaking the PCB off the panel would cause too much stress on the PCB it is wise to use a special tool that will prevent board damage. Just be sure that the tabs are not located near these edge components. Tab-route panelization also allows for boards that have parts overhanging the periphery of the board.

Source: signalintegrityjournal.com

Source: signalintegrityjournal.com

Just be sure that the tabs are not located near these edge components. The three holes make it Tab Routed with Perforations A big advantage to tab routing is the ability to make boards in shapes other than rectangles. With this method PCBs are pre-cut from the array and held in place on the board with perforated tabs. Tab routing is more appropriate when working with unusual shapes. One of the benefits of tab-routing is that you can produce non-rectangular.

Source: tempoautomation.com

Source: tempoautomation.com

PCBs can then be removed by breaking or cutting the tabs that are between the boards in the array. PCBs can then be removed by breaking or cutting the tabs that are between the boards in the array. Fig 8 Tab-routing panel. When V-grooves cant be used design PCB arrays leaving perforated tabs routing space between PCBs. You can still drill holes afterwards if that is what you meant.

Source: seeedstudio.com

Source: seeedstudio.com

Tabbed routing is a new method in which trapezoidal shapes called tabs are added to parallel traces to control impedance in the pin fieldbreakout regions and reduce crosstalk in open field regions. Tabbed routing is a new method in which trapezoidal shapes called tabs are added to parallel traces to control impedance in the pin fieldbreakout regions and reduce crosstalk in open field regions. A mix of scoring and tab routing can be used when some board sides are straight which can be scored while irregular sides must be tab routed. That being the case we recommend that you not put components too close to the tabs. Also tab routing in high volumes takes a lot of time on the router and may drive your cost up.

Source: mermarinc.com

Source: mermarinc.com

If you feel that breaking the PCB off the panel would cause too much stress on the PCB it is wise to use a special tool that will prevent board damage. But keep in mind V score will give a clear edge after the boards are break away from the panels mouse bite holes will not give a clear edge. Tabbed routing is a new method in which trapezoidal shapes called tabs are added to parallel traces to control impedance in the pin fieldbreakout regions and reduce crosstalk in open field regions. That being the case we recommend that you not put components too close to the tabs. Thicker circuit boards are upwards of 0096 or 0125 use 0020 or greater when room allows for all features from the edge of the card.

Source: pcbgogo.com

Source: pcbgogo.com

Break routing requires the placement of break-out-tabs on both the X Y of the PCB. Tab Routing Panelization. Tab routing is a popular PCB panelizing approach that uses tabs with or without perforations. Tab Routing Tab routing is the best way to set up parts relative to the tooling process. Submit a FREE DFM Today.

Source: medium.com

Source: medium.com

If you feel that breaking the PCB off the panel would cause too much stress on the PCB it is wise to use a special tool that will prevent board damage. Tab routing is a popular PCB panelizing approach that uses tabs with or without perforations. Tab-route panelization also allows for boards that have parts overhanging the periphery of the board. Keep traces and surface-mounted parts 18. Thicker circuit boards are upwards of 0096 or 0125 use 0020 or greater when room allows for all features from the edge of the card.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title tab routing pcb by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.